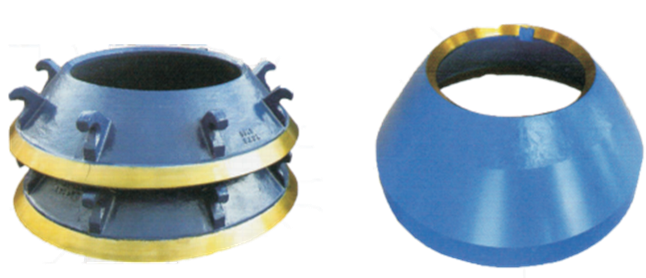

CONE CRUSHER SPARE PARTSCONE CRUSHER SPARE PARTSCone crusher is a primary crusher, used in mining or Ore processing. It reduces large aggregates to smaller aggregate. VSI means, 'Vertical Shaft Impactor'. In which shaft and crushing chamber are in a vertical position which is a latest crushing technology. The crushing action is caused by the closing of the gap between the mantle line (movable) mounted on the central vertical spindle and the concave liners (fixed) mounted on the main frame of the crusher. The stone or material fed at the center of the rotor, which is rotating at high RPM accelerate the material and material is thrown out from the rotor with a vigorous velocity of 300 ft. per sec. The main advantage of this process is material breaks at the minimum surface area, which makes the particle of cubical/spherical shape and brings consistency in size. The Cone crusher its advantage is to having a large crushing ratio, high efficiency, low energy consumption, and uniform product particle size. Mantle types serve as movable cones, fixed on the cone body with a conical head, forged from new composite material, ensuring super wear-resistance, high performance to cost ratio, and wide application fields. Concave types, constituting the main part that breaks the wall alongside the broken cone, are crucial for efficient material breakage, and are fixed, hence referred to as fixed cones. Elevate your cone crusher experience now with our accessories. Choose between mantle and concave types, each crafted for efficiency and durability. Suitable for a variety of materials and applications, our cone crusher accessories promise superior performance. |